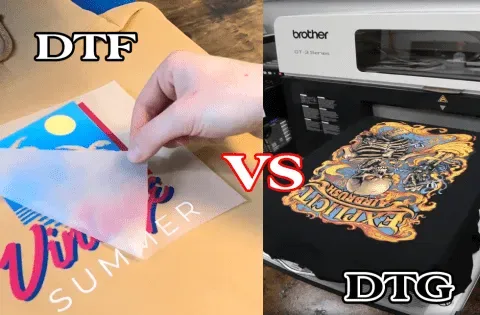

When it comes to custom apparel printing, DTF vs DTG are two prominent methodologies that many businesses and creators explore. Direct to Film (DTF) and Direct to Garment (DTG) both serve the purpose of delivering vibrant, eye-catching designs on various textiles, yet they employ markedly different printing techniques. DTF printing focuses on applying designs to a film before transferring them to the fabric, making it versatile across fabric types. In contrast, DTG printing utilizes specialized inkjet printers that apply water-based ink directly onto garments, primarily suited for natural fibers such as cotton. Understanding the nuances between these two approaches can ensure you choose the right method to achieve stunning garment printing results that align with your project needs.

In the realm of garment decoration, two distinct printing methodologies stand out: the film transfer technique and the direct application method. The film transfer process, often referred to as DTF, employs a special film to achieve vibrant prints on a variety of materials, making it an adaptable option for many applications. Conversely, the direct application technique, commonly known as DTG printing, excels at delivering intricate designs directly onto fabrics, particularly cotton. Each method offers unique advantages that cater to different production needs and design complexities, making it essential to evaluate which is best suited for your specific custom apparel project.

Understanding DTF vs DTG Printing: Key Differences

When comparing DTF and DTG printing methods, it’s essential to recognize their fundamental differences. DTF, or Direct To Film printing, uses a transfer film to print designs that are then heat-pressed onto the fabric. This specialized method allows for versatile applications across various fabric types, including polyester and blends, enabling designers to explore a broader range of garments. In contrast, DTG, or Direct To Garment printing, applies ink directly onto pre-treated cotton fabrics using a specialized inkjet printer. This approach excels in achieving intricate and colorful designs but is primarily limited to natural fibers.

The distinction in application also affects print quality and durability. DTF printing tends to deliver bright, bold colors with good durability, especially on darker fabrics, as it can layer designs effectively. On the other hand, DTG can produce high-resolution prints, which are ideal for detailed images but often rely on the absorption properties of the fabric to achieve the best results. In short, understanding DTF vs DTG can aid businesses in selecting the method that best aligns with their printing needs and garment specifications.

Advantages of DTF Printing for Custom Apparel

One of the primary advantages of DTF printing is its flexibility in fabric applications. Unlike DTG, which is best suited for 100% cotton fabrics, DTF printing shines by being compatible with a variety of materials, including synthetic fibers like polyester. This versatility allows businesses to cater to a wider range of customers and product offerings, making DTF a popular choice for those looking to create custom apparel across different fabric types. Moreover, the vibrant colors produced through this technique remain true even on darker backgrounds, elevating the visual impact of the designs.

Additionally, DTF printing is highly beneficial for production efficiency. The ability to print multiple transfer films in one run significantly boosts production speed, particularly in bulk orders. This makes it an attractive option for businesses aiming to fulfill larger quantity requests without compromising on quality. With lower costs per unit for high-volume orders, DTF printing not only improves workflow but also enhances profitability, making it a compelling choice for anyone in the custom apparel printing market.

Benefits of DTG Printing for Detailed Designs

For projects requiring extremely detailed designs, DTG printing is often the superior choice. The high-resolution capabilities of DTG technology allow for intricate graphics and a vast color spectrum, making it ideal for artists and brands that want to showcase complex artworks or vibrant images. Because DTG prints feel soft to the touch—almost as if the ink is a part of the fabric—this method provides a comfortable wear experience that many customers appreciate, particularly in fashion and apparel.

Another advantage of DTG printing is its environmentally friendly approach, as it predominantly uses water-based inks. This eco-conscious choice resonates strongly with consumers who prioritize sustainability in their purchasing decisions. Furthermore, DTG’s ability to handle small batch sizes efficiently makes it particularly attractive for independent artists and startups looking to test their designs without investing heavily in inventory. This model allows creators to offer unique pieces while minimizing waste, aligning perfectly with modern consumer values.

Production Speed: DTF vs DTG Explained

When it comes to production speed, DTF printing holds a clear edge over DTG printing, especially in bulk production scenarios. DTF allows for multiple designs to be printed simultaneously on transfer films, which can then be heat-pressed onto multiple garments in a streamlined process. This efficiency is crucial for businesses looking to meet tight deadlines or fulfill large orders quickly. As a result, DTF is often favored for commercial print runs where time efficiency translates to profitability.

In contrast, DTG printing works on a per garment basis and can be slower due to its need for individual treatment and printing of each piece. This method is more suitable for smaller productions or when unique, customized pieces are required. While DTG may not compete with DTF in terms of speed, it compensates for this with its ability to produce highly detailed prints that cater to a niche audience. Ultimately, businesses need to assess their production needs to determine whether the speed of DTF or the quality of DTG best meets their objectives.

Fabric Compatibility: Choosing the Right Printing Technique

When selecting a printing technique, fabric compatibility is a pivotal consideration. DTF printing has the distinct advantage of working effectively on a broad range of materials, including cotton, polyester, and even blends. This flexibility allows brands to experiment with diverse textiles and cater to different garment styles, significantly widening their product offerings. Whether creating sportswear, leisure clothing, or fashionable accessories, DTF enables designers to achieve high-quality prints on virtually any fabric.

On the other hand, DTG printing is most effective on natural fibers, particularly 100% cotton. This limitation means that while the print quality is exceptional on these materials, businesses may miss out on opportunities to print on popular synthetic blends or darker fabrics where DTF shines. Thus, understanding the fabric type you plan to use is essential in making an informed choice between DTF and DTG printing, ensuring optimal results that meet customer expectations.

Cost-Effectiveness of DTF vs DTG Printing

Cost considerations play a significant role in deciding between DTF and DTG printing. Direct To Film printing often requires a higher initial setup investment due to the necessary equipment and materials, but it offers considerable savings in high-volume situations. As the price per print decreases with larger orders, businesses that focus on bulk production can benefit significantly from this method. Therefore, DTF printing can be particularly attractive for companies looking to produce large quantities of custom apparel.

Conversely, DTG printing might seem more expensive for small runs due to its higher cost per unit; however, it provides exceptional quality for those seeking intricate and detailed designs. For businesses that anticipate varying order sizes, DTG can still be cost-efficient because it allows for lower waste and inventory management challenges. Ultimately, evaluating the scale of production and the type of designs will aid in determining the most financially viable option for your needs.

Frequently Asked Questions

What are the main differences between DTF printing and DTG printing?

DTF printing (Direct To Film) prints designs onto a special transfer film which is then heat-pressed onto garments, offering versatility across various fabrics. In contrast, DTG printing (Direct To Garment) applies ink directly to pre-treated fabrics, mainly cotton, resulting in high-resolution, colorful designs. While DTF is better for bulk orders and diverse textiles, DTG excels in intricate details on cotton.

Is DTF printing more cost-effective than DTG printing for large orders?

Yes, DTF printing is often more cost-effective for larger orders. Though DTF’s initial setup costs can be higher, the cost per print decreases significantly for bulk quantities, making it an economical option for businesses needing high-volume custom apparel printing compared to DTG.

Which printing technique, DTF or DTG, works better on dark fabrics?

DTF printing generally offers superior results on dark fabrics. Its transfer method allows for vibrant colors and effective layering, ensuring that prints remain bright and dynamic, whereas DTG may require pre-treatment for color visibility on darker materials.

Can I use DTF printing on various fabric types compared to DTG printing?

Yes, DTF printing is notably versatile, working well on a range of materials beyond just cotton, including polyester and blends. DTG printing, however, is predominantly effective on 100% cotton fabrics, limiting its fabric compatibility.

What factors should I consider when choosing between DTF and DTG printing?

When choosing between DTF and DTG printing, consider factors such as design complexity (DTG for intricate designs), production volume (DTF for bulk), fabric types (DTF for variety), durability (DTF for longevity), and cost-effectiveness based on your print needs.

How does the print quality of DTF printing compare to DTG printing?

DTG printing is renowned for its high-resolution output, making it ideal for detailed and complex designs. In contrast, DTF printing also achieves vibrant quality and allows better layering, especially on diverse fabrics, which can enhance visual appeal in both methods.

| Key Factor | DTG (Direct To Garment) | DTF (Direct To Film) |

|---|---|---|

| Process Overview | Utilizes a specialized inkjet printer to apply water-based ink directly onto pre-treated garments. | Prints designs on special transfer film, which are then heat-pressed onto garments. |

| Ink Type | Primarily uses water-based inks, resulting in soft prints that blend with fabric. | Combines water-based inks with adhesive powders for versatility across various fabrics. |

| Suitable Fabrics | Best for natural fibers like cotton, which absorb inks well. | Works excellently on multiple materials, including polyester and blends. |

| Print Quality | High resolution, ideal for intricate designs and vibrant colors. | Vibrant colors with good layering; especially effective on darker fabrics. |

| Production Speed | Relatively slower, especially for larger orders since each piece is printed individually. | Faster production, especially for bulk orders due to multi-transfer capability. |

| Cost Consideration | Higher cost per print for smaller batches, but becomes competitive in larger orders. | Initial setup costs are higher, but cost per print decreases significantly for bulk orders. |

Summary

In the debate between DTF vs DTG printing, it’s essential to consider the specific needs of your project. DTG printing excels with detailed, colorful designs on cotton fabrics, making it ideal for small, intricate orders. Conversely, DTF printing provides flexibility for varying fabric types and faster production times, which is particularly advantageous for larger volume orders. Depending on your focus—be it quality detail with DTG or versatility with DTF—understanding these key differences will aid in selecting the printing method that best aligns with your requirements.