DTF Transfers, or Direct-to-Film transfers, have revolutionized the custom apparel industry, becoming a key player in modern printing techniques. These innovative transfers allow for high-quality, vibrant designs to be efficiently applied onto various fabrics, offering remarkable durability and resilience. With the ability to handle intricate designs that traditional methods like screen printing often struggle with, DTF printing advantages are becoming increasingly recognized among professionals and hobbyists alike. As the DTF market trends continue to evolve, the possibilities for unique creations in custom apparel seem endless. Discover how this exciting technology can transform your textile projects and enhance your brand’s offerings.

Direct-to-Film printing technology, often referred to as DTF printing, is gaining momentum in the world of textile decoration. This method stands out due to its versatility, enabling creators to transfer stunning graphics onto a wide range of fabrics seamlessly. In a market driven by customization and artistic expression, heat transfer techniques like DTF have established themselves as essential resources for both businesses and individuals. Moreover, as advancements in the industry lead to improved products and processes, the opportunities for enhancing apparel design are more prominent than ever. Embrace these innovative approaches to bring your creative ideas to life in the custom apparel landscape.

Understanding the Basics of DTF Printing

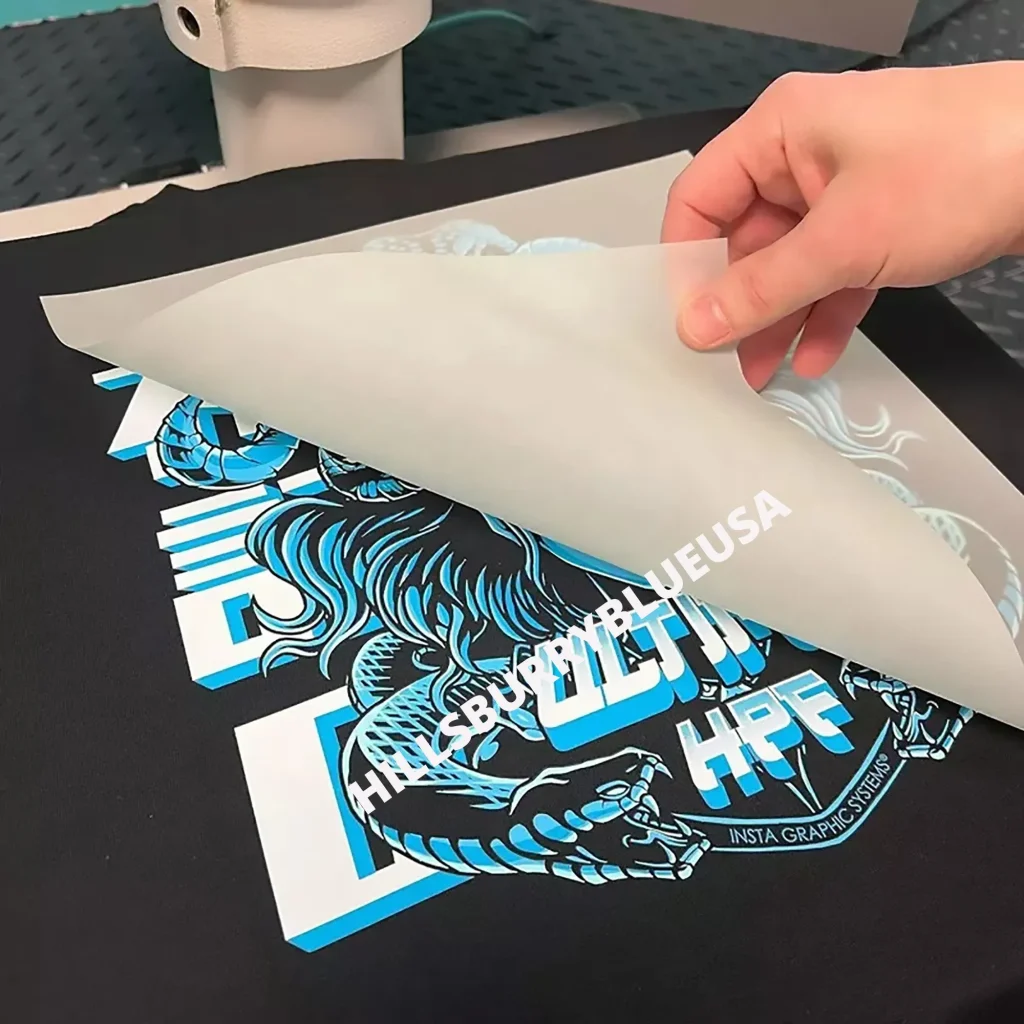

Direct-to-Film (DTF) printing is revolutionizing the landscape of custom apparel production. This innovative method involves printing designs onto a special film, which is then heat pressed onto various fabrics. The result is a vibrant, detailed image that can endure through washes while maintaining its integrity. Unlike traditional printing methods, DTF offers a greater level of precision and an extensive color palette, making it an ideal solution for businesses looking to create eye-catching apparel.

The ability of DTF printing to cater to multiple fabric types, including cotton, polyester, and blends, sets it apart from other techniques. This adaptability ensures that businesses can meet diverse customer needs, providing tailored solutions for different textile preferences. Furthermore, as the technology advances, the quality of prints produced by DTF systems continues to improve, cementing its role in modern textile decoration.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a method of applying vibrant designs onto fabrics. In this process, images are first printed onto a special transfer film. The film is then applied to the fabric using a heat press, which ensures that the design is transferred with high detail and durability, making DTF a popular choice for custom apparel.

What are the advantages of using DTF printing for custom apparel?

DTF printing offers several advantages for custom apparel, including versatility in applying designs to various fabric types, durability of prints that withstand washing, and cost-effectiveness in small production runs. These benefits make DTF transfers an appealing option for both businesses and hobbyists crafting unique designs.

How does DTF printing compare to other methods like screen printing?

Compared to screen printing, DTF printing allows for more intricate designs and a broader color palette with less setup time. Additionally, DTF transfers are more cost-effective for small batches, whereas screen printing is typically better for larger quantities due to its setup costs. This makes DTF a flexible alternative in the custom apparel market.

What recent trends are shaping the DTF market?

Recent trends in the DTF market include the emergence of innovative solutions like Insta DTF, which enhances heat transfer applications. Companies such as Sam’s DTF Transfers are leading the way, offering premium services that cater to the growing demand for DTF printing, especially in e-commerce and small business sectors.

Can DTF transfers be applied to any type of fabric?

Yes, DTF transfers can be applied to a variety of fabrics, including cotton, polyester, and blended materials. This adaptability makes DTF an excellent choice for businesses looking to create custom apparel for diverse customers, catering to various fabric preferences.

What tips should I follow to achieve the best results with DTF printing?

To achieve optimal results with DTF printing, focus on using high-quality materials, like films and inks, and follow recommended heat press settings for temperature and pressure. Additionally, ensure your designs are optimized for high resolution and practice the transfer process to refine your technique for better quality outcomes.

| Key Aspect | Description |

|---|---|

| What is DTF Printing? | Direct-to-Film (DTF) printing transfers designs onto fabrics using a special film and heat press for vibrant, durable designs. |

| Advantages of DTF Transfers | 1. Versatile for various fabric types. 2. Durable prints withstand washing. 3. Cost-effective for small runs. 4. High-quality detailed images. |

| Recent Developments | 1. Sam’s DTF Transfers became a market leader with premium services for small businesses. 2. Insta DTF offers a universal heat transfer solution enhancing efficiency and quality. |

| Practical Tips | 1. Use high-quality materials. 2. Follow heat press guidelines. 3. Optimize your designs for DTF. 4. Practice to improve your results. |

Summary

DTF Transfers revolutionize the world of custom apparel by offering a seamless method to transfer intricate designs onto fabrics. As a versatile, durable, and cost-effective solution, DTF Transfers are quickly becoming a preferred choice for both businesses and hobbyists. The constant evolution of technology, exemplified by industry leaders such as Sam’s DTF Transfers and innovative products like Insta DTF, highlights the growing trust and excitement around DTF printing. By embracing DTF Transfers, users can tap into a vibrant medium for textile design and experience unmatched creative possibilities.